Validation structure: OpenLAB

The openLAB research bridge was constructed within the IDA‑KI project (FKZ 19FS2013A–D), funded by the Federal Ministry for Digital and Transport (BMDV) under the mFUND initiative. The structure serves as a controllable, instrumented demonstrator that reproduces common German road-bridge construction types (≈70%) and representative damage mechanisms and supports progressive loading up to the ultimate limit state (ULS). Datasets acquired during a one-year reference period and during subsequent damage tests are intended for training and validation of automated condition-assessment algorithms and for dissemination to the research community.

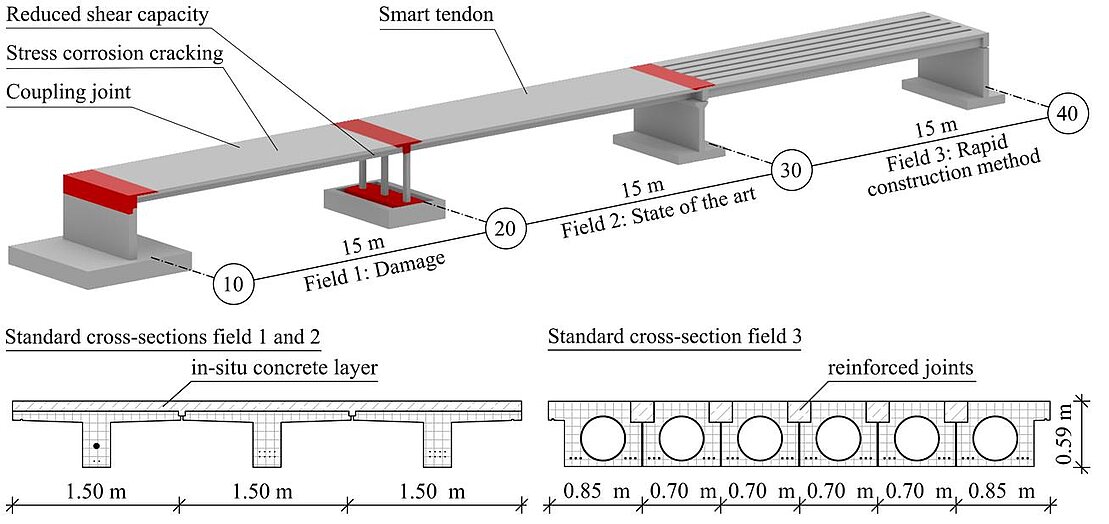

The superstructure comprises three spans, total length 45 m, assembled from precast elements (PE). Fields 1 and 2 each consist of three PE with slab–beam cross sections and conventional cast-in-place topping. Field 1 reproduces legacy defects and damage mechanisms, such as coupling-joint deficiencies, stress-corrosion cracking, localized reduced shear capacity. Field 2 represents contemporary precast practice and incorporates a Smart Tendon in PE 2.1 with embedded distributed fiber-optic sensors (DFOS). Field 3 implements a rapid-construction system: precast units include steel cylinders to reduce dead load and achieve immediate post-assembly loadability via grouted reinforced transverse joints. Design loading was reduced to 25 % of Load Model 1 (LM1) according to DIN EN 1991-2 to permit realistic ULS testing with moderate logistical effort.

(https://tu-dresden.de/bu/bauingenieurwesen/imb/forschung/grossprojekte/openLAB#section-3-3)

The experimental campaign comprises (1) a 12-month reference phase to record baseline structural behaviour under environmental variation and light, simulated traffic and (2) a staged test phase with controlled static and dynamic loading up to ULS to produce labelled damage cases and sensor-fault scenarios. Traffic simulation is achieved with a rail-guided load vehicle performing ≥15 traverses per month and additional targeted runs on extreme temperature days. Static loads are applied via hydraulic presses and load traverses; dynamic excitation is provided by the load vehicle and by an electrodynamic exciter (“shaker”) to enable modal and frequency-domain investigations. Two static campaigns were completed in May 2025 and September 2025, targeting PE 2.1 and Field 1, respectively.

A multi-scale monitoring system captures global and local responses. One accelerometer and one inclinometer are installed at each precast element axis in Fields 1–2, complemented by strain gauges, LVDTs and component temperature sensors at critical details (notably coupling joints). Environmental parameters (air temperature, relative humidity, solar radiation, precipitation) are logged at 10-minute intervals. Approximately 1.5 km of DFOS was installed to provide distributed strain and temperature sensing along tendons and structural members. To process high-volume DFOS output, fosanalysis, an open-source Python toolkit for ingestion, preprocessing and extraction of condition indicators, is employed. Data acquisition configurations are arranged to support modal identification, long-term trend analysis and event annotation.