Monitoring data-driven service life management with AR based on an adaptive, AI-supported corrosion prognosis for infrastructures made of reinforced concrete under combined influences

Initial Situation/ Relevance

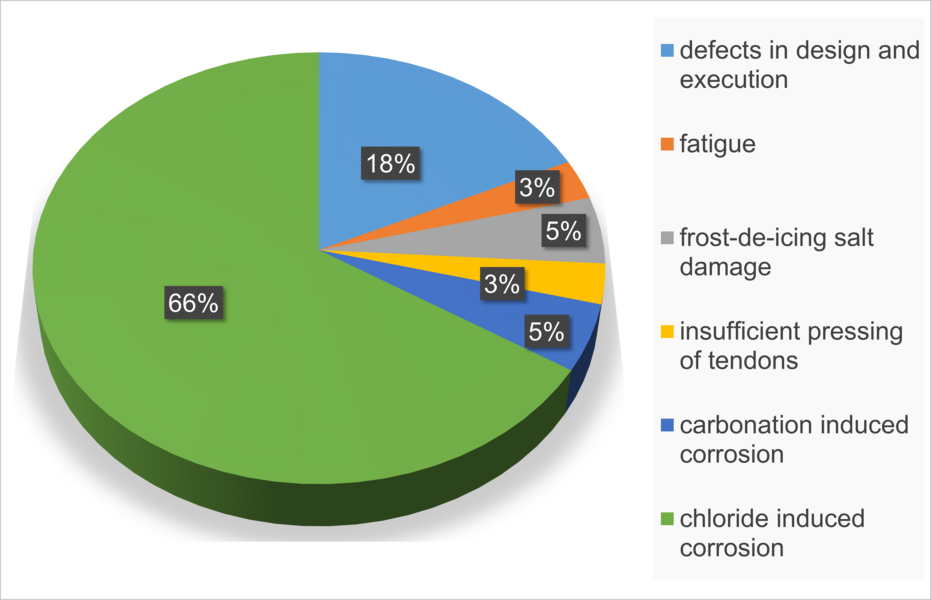

There are more than 39,000 bridges in the German federal trunk road network, approximately 85% of which are made of reinforced and prestressed concrete. Over half of these engineering structures are 40 to 50 years old (BASt 2021). Aging and material fatigue due to environmental exposure and increasing traffic loads damage the structural substance, thereby endangering the reliability and performance of the entire transport system. In this context, chloride-induced reinforcement corrosion is the primary cause of damage (see Figure 1).

Objectives of the Project

The project investigates a method for adaptive service life prognosis of reinforced concrete infrastructures under chloride exposure and mechanical loading combined. The approach is based on continuously adapting a prognosis model using selected and processed sensor data. For the evaluation of locally recorded, partly faulty measurements as well as for the parametrization of the model, machine learning methods are employed. In particular, neural networks continuously assess the structural condition and adjust the service life prediction dynamically.

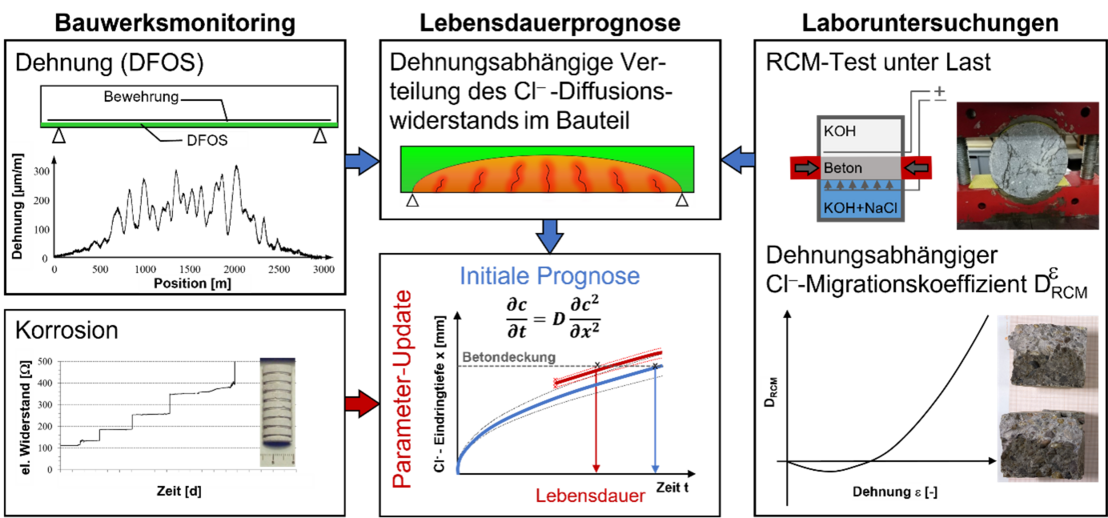

The systematics illustrated in Figure 2 demonstrate the adaptive service life prognosis principle: The material resistance against chloride migration under a given load level is determined at the beginning of service life and combined with locally measured strains at the structure using distributed fiber optic sensors (DFOS). This yields a load-dependent diffusion resistance, which forms the basis for an initial spatially resolved service life estimation. As the structure ages, this prognosis is continuously updated using corrosion wire sensors, which indicate the progression of the corrosion front through wire breaks, thereby enabling a temporally and spatially resolved model adjustment.

Selected sensor and prognosis data are aggregated within a central database of a digital twin. By correlating with the structural geometry and the reinforcement layout, potential problem areas can be localized and visualized directly on the structure using Augmented Reality (AR), see Figure 5. This facilitates the targeted identification of damages not yet visible on the surface during structural inspections. The adaptive prognosis thus supports a predictive, condition-based planning and localization of future repair measures.

The project is managed as a cooperation between Dirk Lowke (building materials and building maintenance) and Henning Wessels (data-driven modelling) to examine the research questions addressed, both about the structural engineering and concrete technology aspects, and about artificial intelligence in sufficient depth.

Spotlights

1. Sustained Load Tests on Substitute Structures

1.1 Objective

Investigation of chloride ingress in cracked reinforced concrete components under sustained static load

1.2 Experimental Conditions

- Test setup: Four-point flexure test

The constant bending moment between the inner bearings induces targeted crack formation in the tensile zone and defines the region of chloride exposure. - Strain monitoring: Distributed Fiber Optic Sensors (DFOS)

Continuous, spatially resolved detection of crack width development in the tensile zone via bonded glass fiber sensors. - Corrosion monitoring:

Depth-resolved and time-dependent detection of corrosion initiation via:- Corrosion wire sensors → Detection of corrosion initiation through wire break (sudden increase in electrical resistance)

- Anode ladders → Measurement of corrosion current

- Core drilling:

Determination of chloride penetration depth using colorimetric indicators to verify sensor data.

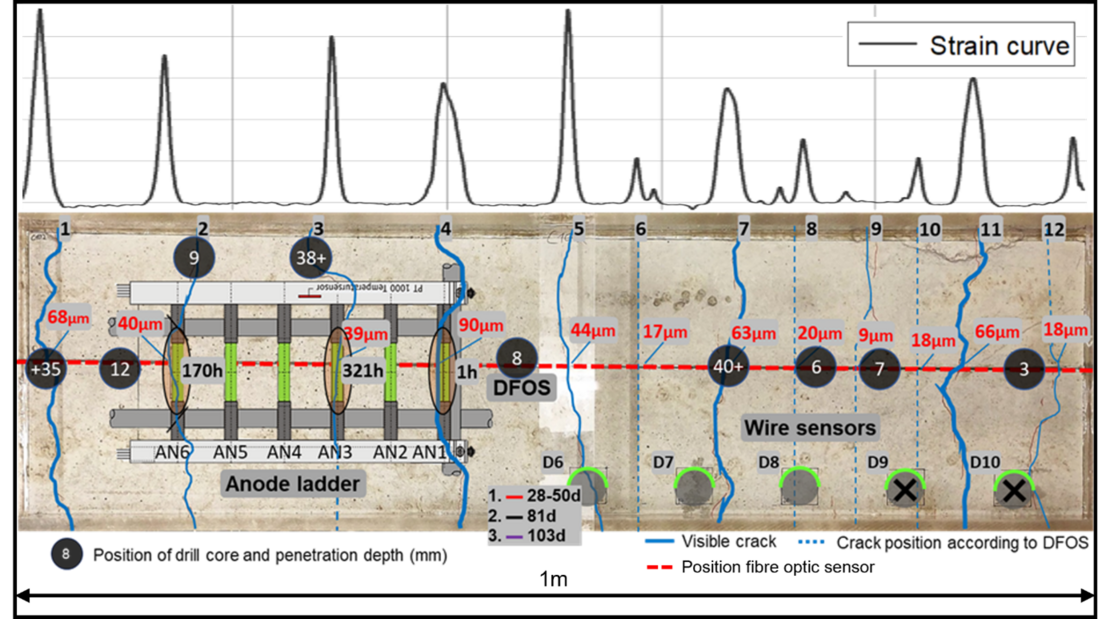

1.3 Results (cf. Figure 3):

- Strain and crack width:

- Top: Spatially resolved strain curve along the midspan

- Derived from DFOS: Crack locations and widths (µm)

- Corrosion monitoring:

- Left: Anode ladder with six steps (concrete cover AN1: 5 mm to AN6: 25 mm), indicated corrosion onset in hours

- Right: Wire sensors (concrete cover 15, 20, 25 mm), wire break in days, X = sensor failure

- Core samples: Marked locations with color change indicating chloride ingress, depth in mm

1.4 Current Status

Continuation of the test series for model parameterization and generation of training data for AI-based prognosis models.

2. Adaptive Service Life Prognosis

2.1 Objective

Service life prediction based on continuously recorded sensor data

2.2 Concept

- Continuous model calibration using artificial intelligence (AI) based on measurement data from corrosion monitoring

- Corrosion wire sensors with depth-discretized wires detecting the progression of the corrosion front

- Corrosion onset is identified through a sudden increase in electrical resistance due to a wire break

- Adaptive model adjustment via Bayesian optimization based on temporally and spatially discretized sensor data

3. Validation on a Real Structure

3.1 Objective

Validation of the adaptive service life prognosis based on corrosion wire sensors embedded in the research bridge "Concerto", see Figure 4.

4. Digital Twin and Visualization with AR

4.1 Objective

Concept for integrating AR applications, displaying virtual content on two levels.

4.2 Implementation

- First level: Graphical overlays on the component surface

- Second level: Pop-up elements and visualization of measurement and prognosis data

Contact

Publications

Publications

[Ant25] Anton, David, Tröger, Jendrik-Alexander, Wessels, Henning et al. „Deterministic and statistical calibration of constitutive models from full-field data with parametric physics-informed neural networks”. Advanced Modeling and Simulation in Engineering Sciences 12, 12 (2025). doi.org/10.1186/s40323-025-00285-7

[Bec24] Becks, H.; Lippold, L.; Winkler, P. et al.: Neuartige Konzepte für die Zustandsüberwachung und -analyse von Brückenbauwerken – Einblicke in das Forschungsvorhaben SPP100+. In: Bauingenieur 99 (2024), Heft 10, S. 327-338. doi.org/10.37544/0005-6650-2024-10-63.

[Dre15] Dreßler, Inka; Wichmann, Hans-Joachim; Budelmann, Harald (2015): Korrosionsmonitoring von Stahlbetonbauwerken mit einem funkbasierten Drahtsensor. Bautechnik 92(2015)10, S. 683–687. DOI: 10.1002/bate.201500051.

[Hol10] Holst, Alexander; Budelmann, Harald; Wichmann, Hans-Joachim (2010): Korrosionsmonitoring von Stahlbetonbauwerken als Element des Lebensdauermanagements. Beton- und Stahlbetonbau 105(2010)12, S. 536–549. DOI: 10.1002/best.201000066.

[Low08] Lowke, D.; Schmidt, K.; Schießl, P.; Heinz, D.: Dauerhaftigkeitspotentiale selbstverdichtender Betone: Auswirkungen der Betonzusammensetzung auf Dichtigkeit, Carbonatisierung, Frostwiderstand und Alkali‐Kieselsäure‐Reaktion. Beton‐und Stahlbetonbau 103(2008)5, S.324-333

[Men20] Mengel, L.; Krauss, H.W.; Lowke, D.: Water transport through cracks in plain and reinforced concrete–Influencing factors and open questions. Construction and Building Materials 254, 118990

[Mil12] Milachowski, C.; Lowke, D.; Gehlen, D.: Detection of transport processes during freeze-thaw deicing salt attack using single-sided NMR. Proc. of 2nd Conference on Microdurability, Amsterdam, 11.-14.04. 2012

[Nar25a] Narouie, V., Wessels, H., and Römer, U.: Inferring displacement fields from sparse measurements using the statistical finite element method. Mechanical Systems and Signal Processing, 2025. doi.org/10.1016/j.ymssp.2023.110574

[Nar25b] Narouie, V., Wessels, H., Cirak, F., and Römer, U.: Mechanical State Estimation with a Polynomial-Chaos-Based Statistical Finite Element Method. Comput. Methods Appl. Mech. Engrg., 2025. doi.org/10.1016/j.ymssp.2023.110574

[Pot24] Potnis, A.; Macier, M.; Leusmann, T.; Anton, D., Wessels, H.; Lowke, D. (2024): Model-based reinforcement corrosion prediction: Continuous calibration with Bayesian optimization and corrosion wire sensor data. arXiv Preprint. DOI: 10.48550/arXiv.2411.16447.

[Roe25] Römer, U., Hartmann, S., Tröger, J., Anton, D., Wessels, H., Flaschel, M., and De Lorenzis, L.: Reduced and All-at-Once Approaches for Model Calibration and Discovery in Computational Solid Mechanics. ASME. Appl. Mech. Rev., 2025. doi.org/10.1115/1.4066118

[Shi24] Shivalingappa, G., Anton, D., & Wessels, H.: Parametric Neural Networks as Full-Field Surrogates for Material Model Calibration. Proceedings of the 10th European Workshop on Structural Health Monitoring (EWSHM 2024), June 10-13, 2024 in Potsdam, Germany. e-Journal of Nondestructive Testing . doi.org/10.58286/29583

[Thi16] Thiel, C.; Beddoe, R.E.; Lowke, D.; Gehlen, C.: Investigating the role of moisture on concrete carbonation using single-sided 1H-NMR.2016, Int. RILEM Conference Materials, Systems and Structures in Civil Engineering 2016, S. 261-268

[Ull21] Ullmann, Stefan; Lowke, Dirk: Effect of Young's Modulus on the degradation of repair mortars chloride migration resistance under coupled loading conditions. In: Int. RILEM Conference Microstructure Related Durability of Cementitious Composites, 2021, The Hague, Netherlands, Bd. 4., resolver.tudelft.nl/uuid:1530eaec-7575-4ebb-bb89-80ea9a785cbd